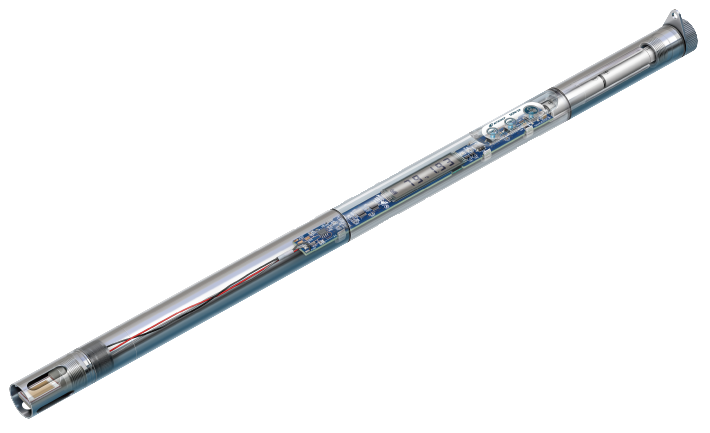

Monitor para Aceite de Freír DOM-24

Bs. 0.00Bs. 0.00

Control Cuantitativo y Fiable del Aceite Deteriorado.

Respaldo IoT PAL equipado con función de transmisión de datos NFC.

Una vez que se degrada el aceite, este debe ser reemplazado con aceite nuevo y fresco. El uso continuo de aceite viejo o degradado puede tener varias consecuencias negativas.

No sólo afecta la calidad y el sabor de los alimentos, sino que también puede afectar gravemente a la salud de sus clientes.

Mediante el control de calidad y evaluación del estado del aceite degradado, usando valores objetivos y cuantitativos, se puede determinar el momento adecuado para cambiar el aceite.

También puede ser muy útil en la reducción de costos y la mejora de la calidad y el sabor de sus productos alimenticios. La gestión eficiente le permite maximizar la vida útil del aceite.

Cuando se degrada el aceite, peróxidos nocivos se producen a partir de los ácidos grasos insaturados en el aceite.

Además la oxidación hace que el aceite se vuelva cada vez más degradado.

Un contrôle efficace vous permet d’optimiser la durée de vie de l’huile.

El uso de este aceite de baja calidad, degradado gravemente para cocinar o freír puede conducir a problemas de salud graves, como la acidez estomacal o náuseas.

ATAGO recomienda utilizar el DOM-24 para revisar periódicamente y supervisar la calidad de su aceite con el fin de maximizar su vida útil.

Sin complicaciones y fácil de usar

La titulación requiere equipos problemáticos y una preparación que requiere mucho tiempo. Usar laboratorios de terceros es bastante costoso.

Le DOM-24 peut facilement mesurer la dégradation de l’huile sans aucune configuration compliquée. El DOM-24 puede medir fácilmente la degradación del aceite sin una operación complicada. No se necesita absolutamente ningún otro equipo o preparación.

Fácil de usar

Algunos métodos que utilizan tiras reactivas o kits de reactivos resultan en lecturas subjetivas. Además, requiere conocimientos técnicos y experiencia.

El DOM-24 proporciona valores objetivos y cuantitativos para determinar la degradación del petróleo.

Cualquiera puede obtener mediciones precisas y confiables sin destreza o experiencia.

No más pérdidas de suministros o eliminación de bassura

A diferencia de la titulación, y las tiras reactivas,que se deben desechar cada vez que se toman las mediciones, el DOM-24 no generan desechos o basura, lo que significa que usted no tiene que preocuparse de su eliminación. Esto significa que usted no tiene que lidiar con el gasto de dinero para reemplazar los suministros vencidos.

Seguro, confinable, e higiénico

Muchas personas se sienten incómodas con el uso de productos químicos o reactivos potencialmente peligrosos al evaluar la calidad del aceite, especialmente en las instalaciones donde se producen y manejan los alimentos.

Las mediciones con el DOM-24 son seguras e higiénicas. Después de que se han tomado las medidas, el DOM-24 puede ser completamente lavado con agua corriente, lo que permite un mantenimiento higiénico a fondo.

Con una distancia segura del aceite a la mano, se considera la seguridad para prevenir quemaduras.

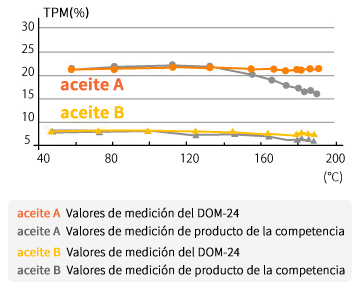

Valor de medición estable incluso a alta temperatura

El papel de prueba y el método de titulación miden después de enfriar el aceite, pero el DOM tiene una función de compensación de temperatura, por lo que admite una amplia gama de temperaturas de 0 ° C a 225 ° C.

Puede medir con confianza incluso a altas temperaturas y no es necesario esperar el tiempo de enfriamiento. Comparación de valores de medición a altas temperaturas

NFC (Sistema de Transmisión de datos via NFC)

El historial de mediciones (hasta de 100 registros) puede ser leído sin contacto por medio de una tarjeta de lectura y escritura a un teléfono inteligente o una computadora personal.

* N-Mark es una marca comercial registrada de NFC Forum, Inc. en los Estados Unidos y en otros países.

Calentador IH compatible (patentado)

El DOM-24 es el único comprobador de aceite que se puede usar con los calentadores IH al colocar la cubierta del sensor.

Un nuevo medidor para verificar la calidad del aceite para que pueda supervisar regularmente el aceite ahora está disponible.

Es fácil de operar, y cualquier persona puede utilizarlo para hacer mediciones.

Este producto, es un indicador que muestra la calidad general del aceite para freír, y le permite medir tanto CPT (compuestos polares totals) como el índice de acidez (IA) que se utiliza para determinar el deterioro de la calidad alimenticia del aceite.

Especificaciones

| Modelo | DOM-24 |

|---|---|

| Cat.No. | 9341 |

| Rango | Compuestos Polares Totales (CPT) : 0.5 a 40.0% Índice de Acidez (IA): 0.00 a 9.99 Temperatura : 0 to 225℃ / 32 to 437°F |

| Resolución | Compuestos Polares Totales (CPT) : 0.5% Índice de Acidez (IA) : 0.01 Temperatura : 1℃/1°F |

| Exactitud | Compuestos Polares Totales (CPT) : ±2.0%(20 to 200℃ / 68 to 392°F) Índice de Acidez (IA) : ±0.2 Temperatura : ±1℃/±2°F |

| Compensación de temperatura | 0 to 225℃ / 32 to 437°F ( Precisión garantizada desde 70 a 190℃) |

| Fuente de alimentación | 2 x Baterías tipo AAA |

| Clase de protección internacional | IP67 |

| Dimensiones y Peso | 22(Φ)×490(W)mm, 400g (unidad principal solamente ) |

Description

Control Cuantitativo y Fiable del Aceite Deteriorado.

Respaldo IoT PAL equipado con función de transmisión de datos NFC.