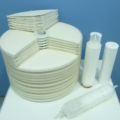

Lenticular Modules

Bs. 0.00Bs. 0.00

Features

- Number of lenticules: 16.

- Module dimensions: 400 mm outer diameter x 50 mm inner diameter x 275 mm height.

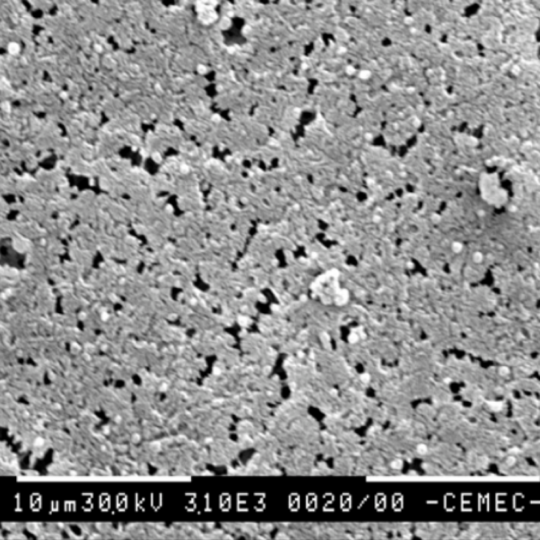

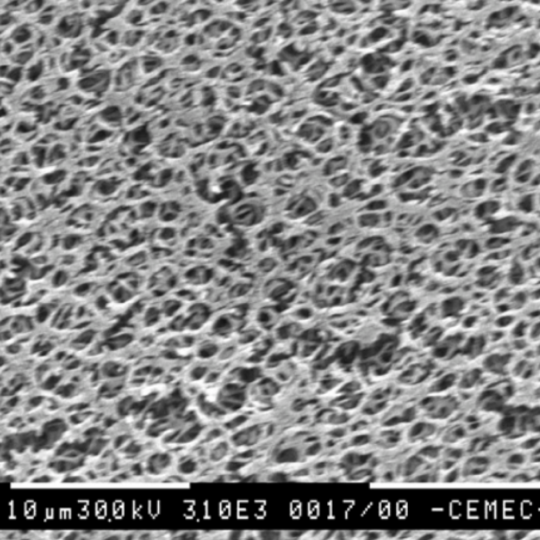

- Filter medium: 4 mm grade alpha cellulose and diatomaceous earth.

- Support skeleton: Natural polypropylene.

- Metal supports: Stainless steel.

- Gaskets: Silicone.

- Filtering surface: 3.6 m2.

- Available pores from 0.3 to 12.0 µm.

- Molded edges and anti-migration discs.

Operating Conditions

- Maximum intermittent operating temperature: 121°C.

- Maximum continuous operating temperature: 80°C.

- Maximum differential pressure: 2.5 bar.

- pH operating range: 4-10

Uses

They are ideal for filtering and clarifying various types of beverages, solvents, or light oil fractions, making them particularly useful in the distilling and petrochemical industries.

Description

The Microclar lenticular module line possesses unique design qualities that ensure resistance and durability during its use. Its internal structure grants it high mechanical strength and a large filtering surface, which guarantees its performance for a longer period. These filter elements are primarily used for high-volume and high-flow applications, making them ideal for filtering and clarifying various types of beverages (especially wines), solvents, or fractions of light oils.

Its injection-molded polypropylene edge encapsulates the filter medium and separator, providing excellent strength to each lenticule and preventing the module from disintegrating when removed after completing the job. The anti-contamination discs prevent filter material fibers from passing into the filtrate. Additionally, these discs prevent the module from shrinking when it is wet.

Housings can be leased.

Advantages of using modules compared to a plate and frame filter press:

- It is a closed and hygienic system, whereas filter presses are open.

- The space required for a module filtration system is much smaller.

- The time needed to replace the filter material is significantly less in the module system.

- The costs of a module housing are much lower compared to a filter press.